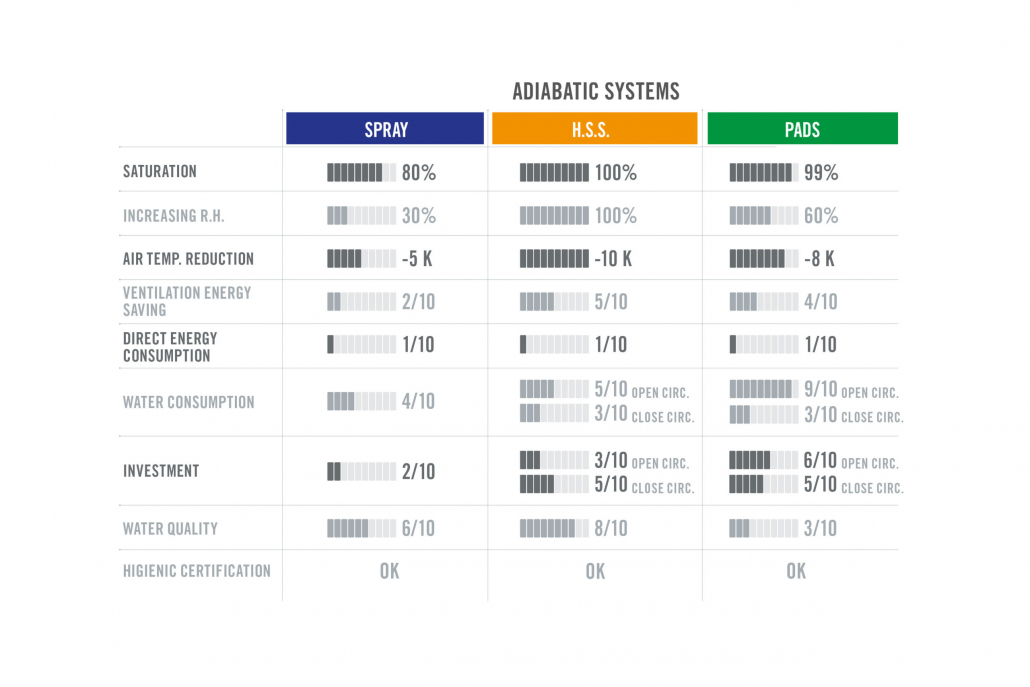

Adiabatic Systems

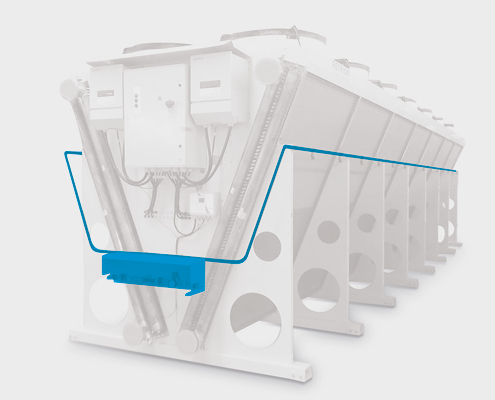

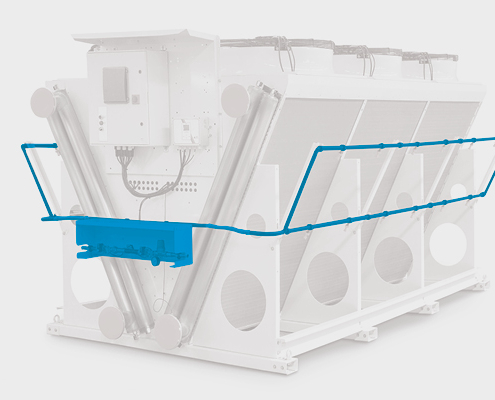

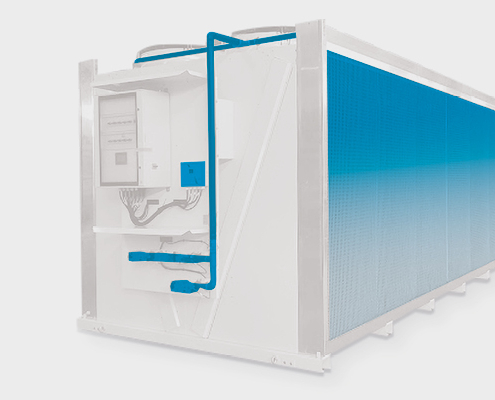

Adiabatic Systems for Dry Coolers and Remote Condensers to boost thermal performance and maximise heat exchanger efficiencies.

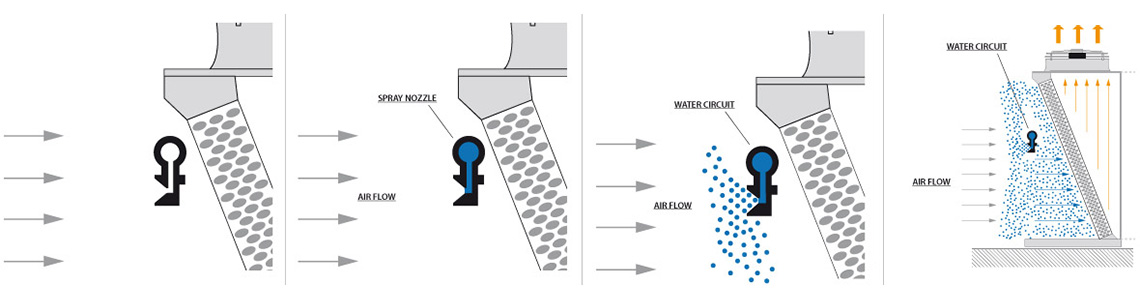

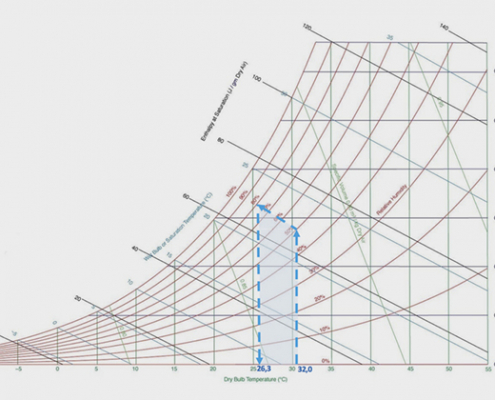

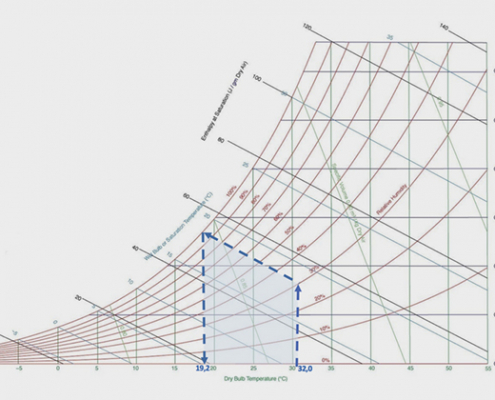

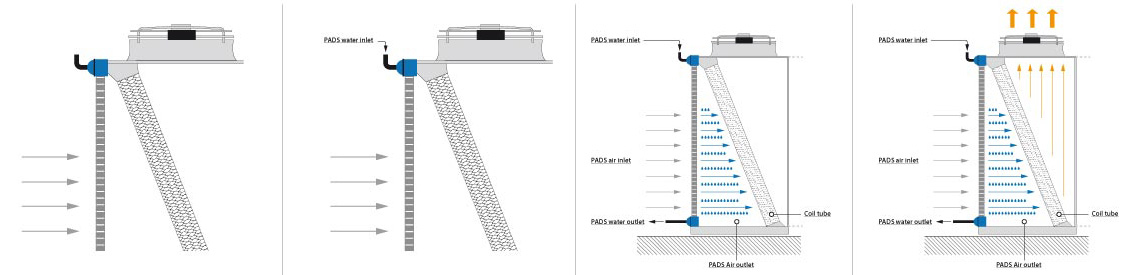

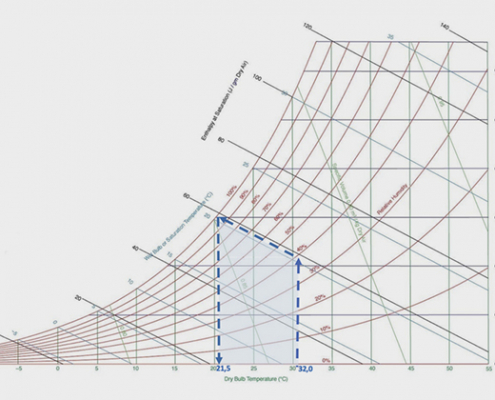

Adiabatic systems for Dry Coolers are able to increase the relative humidity of the air passing through the exchanger, so as to decrease the temperature and increase heat exchange. This happens through the physical principle of the latent evaporation heat in which the water, by evaporating, absorbs heat from the air entering the heat exchanger, lowering its temperature.

The adiabatic saturation reduces the suction air temperature (respect to the ambient air) and therefore the efficiency of the heat exchanger increases. The adiabatic saturation temperature lowers – since evaporating water removes heat – though it is still higher than the dew temperature, as evaporation itself raises the partial pressure of water vapour. The adiabatic saturation guarantees an increase of the relative humidity up to the whole saturation of the air (R.H.=100%)