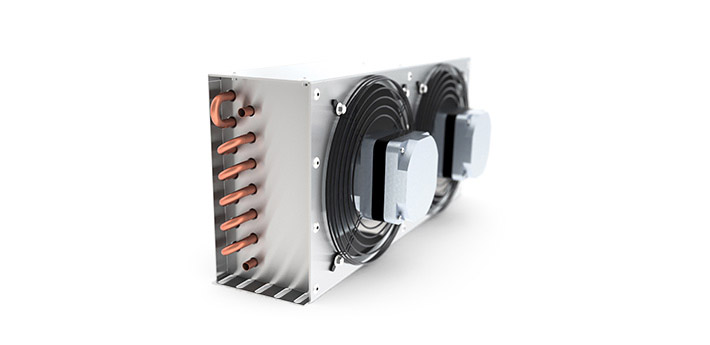

Corrugated aluminium fins

Copper tubes

Remote Air Cooled Condensers

For all refrigeration applications, offering great installation flexibility

Unit Range Overview

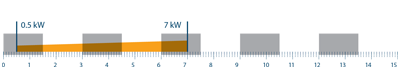

TK SERIES

- Capacity: from 570 to 6900 W

- Fan motor diameters: 172 / 200 / 230 / 254 / 300 mm

- Tube diameter: 8 mm

- Fin spacing: 3.0 mm (customized spacing available on request)

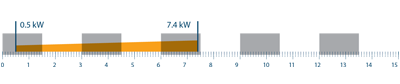

CT SERIES

- Capacity: from 510 to 7400 W

- Fan motor diameters: 172 / 200 / 230 / 254 / 300 mm

- Tube diameter: 7 mm

- Fin spacing: 2.8 mm (customized spacing available on request)

LK SERIES

- Capacity: from 570 to 6900 W

- Fan motor diameters: 172 / 200 / 230 / 254 / 300 mm

- Tube diameter: 8 mm

- Fin spacing: 3.0 mm (customized spacing available on request)

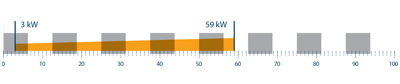

COMMERCIAL SERIES

- Capacity: from 14 to 280 kW

- 3/8” tube diameter: grooved inner surface & high-efficiency fin with 2.1 mm spacing for turbo models

- 3/8” tube diameter: smooth inner surface & corrugated fin with 2.1 mm spacing for standard models

- Fan motor diameters: 450/500 & 630 mm – 4,6,8 & 12 poles

- Available no. fan motors: from 1 to 2×4 fan motors

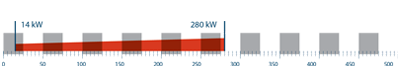

INDUSTRIAL SERIES

- Capacity: from 28 to 626 kW

- 3/8” tube diameter: grooved inner surface & high-efficiency fin with 2.1 mm spacing for turbo models

- 3/8” tube diameter: smooth inner surface & corrugated fin with 2.1 mm spacing for standard models

- Fan motor diameters: 800 & 910 mm – 6,8 & 12 poles

- Available no. fan motors: from 1 to 2×5

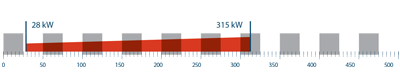

CK SERIES

- Capacity: from 28 to 315 kW

- 3/8” tube diameter: either grooved or smooth inner surface & high-efficiency fin with 2.1 mm spacing for standard / turbo models

- Fan motor diameters: 800 mm – 6,8 & 12 poles

- Simplified casing structure: Designed for applications requiring power & limited weight

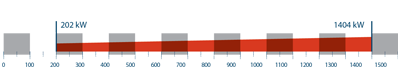

CV SERIES

- Capacity: from 202 to 1404 kW

- Tube diameter: 3/8” grooved inner surface

- Fin spacing: 2.1 mm

- Fan diameter: 910 mm – 6 & 8 poles (800 mm available on request)

- Available no. fan motors: from 2×2 to 2×6

General Features

APPLICATIONS

4D range of air cooled condensers are suitable for any application with all of the new HFC and HCFC refrigerants. The indicated air flows and power consumptions were verified at our manufacturing plants as per EN327.

COILS

The condensers consist of heat exchangers (coils) made of corrugated aluminium fins and copper tubes. The supporting side plates are made of aluminium. The units are designed and assembled according to strict company specifications regarding production and quality, in order to prevent tube damages. Tubes are tested at 33 bar as per Pressure Equipment Directive 2014/68/EU and pre-charged with dry air, to ensure the absence of leaks, humidity and debris in the refrigeration circuit. The T-shaped welding of the inlet and outlet headers guarantees perfect long lasting hold. Headers are equipped with two Schrader valves.

FAN MOTORS

All models are supplied with standard fan motors, certified by our suppliers and tested at our plants. The fan guards and fasteners are made of black painted steel (color code RAL9005) and are manufactured according to the strictest safety standards.

ELECTRICAL

Fan motors and casing are fitted for grounding. All electrical components, cables, terminals, and junction boxes are selected and wired according to European standards.

CASING & FINISH

The casing consists of an internal self-supporting frame made of galvanized or stainless steel, while all of the visible parts and finishing are made of white pre-painted aluminium (color code RAL9010), which gives the unit a clean and polished look. 4D Condensers are supplied with protective films on all pre-painted surfaces. Supports and floor brackets can be assembled on both sides of the condenser, enabling connections on either right or left side. These production materials make the product: light in weight, non-toxic and devoid of polluting particles plus highly resistant to mechanical stress and corrosion

PACKING

All 4D condensers are packed individually in fully enclosed wooden crates. All units are supplied with label and technical specifications, user and maintenance manual, certificate of inspection, manufacturer’s statement, and cable wiring sheet.

- Coil

- Casing & Finish

Galvanized or stainless steel frame

Pre-painted aluminium (color RAL9010)

Lightweight - Fan Motors

All units fitted w/ standard fan motors

- Electrical

All components according to European standards

Fin material options

Customisable headers

Surface treatments

Tube configuration options

Highly customisable frame

Accessories

-

Stainless steel casing

-

ATEX fan motors

-

Pre-painted fins *for models with fan motors Ø350, Ø450, Ø500 and Ø630

-

Reversible version

-

Phase cutting regulators

-

Higher floor brackets

-

Fan motors with different voltages

-

EC Fan motors

-

Service switches

-

Multiple circuits

-

Inverters

-

Copper fins

-

Fan motor wiring

Flyer

Download

Click to download your copy of the Air Cooled Condenser Flyer.

Format: PDF

File size: approx 2 MB

ADDRESS

Unit 13 Endeavour Park

Baker Road

Cramlington

Northumberland

NE23 1XA

United Kingdom

Tel. +44 (0)1670 739964

M. +44( 0)7813 352 622

E. sales@4dcoils.co.uk

Business Hours

Mon – Fri: 08:00-17:00 GMT

Saturday: closed

Sunday : closed