Materials: copper, aluminium

Different geometries

Special treatments including hydrophillic & pre-painted

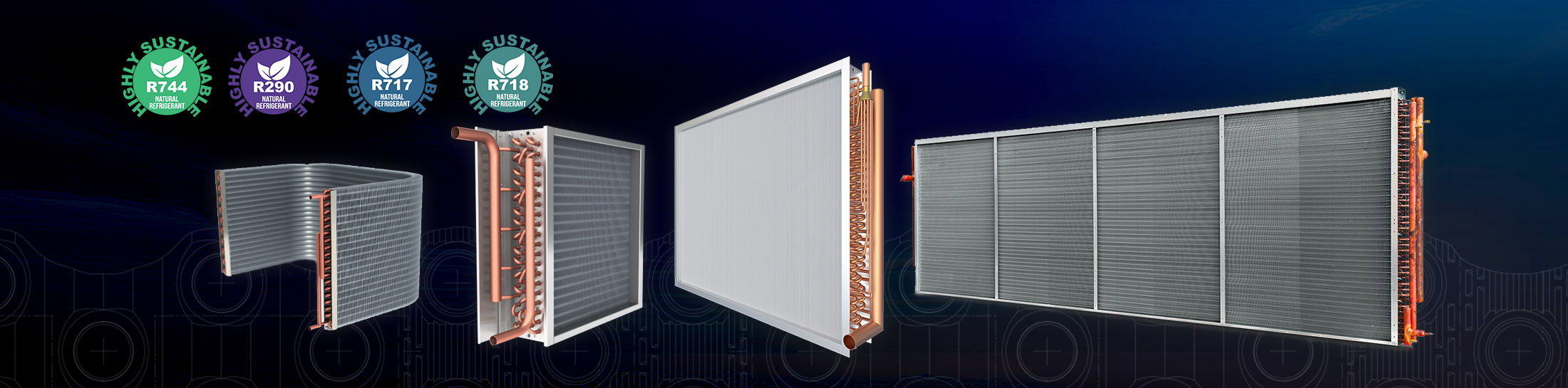

Main Product Groups

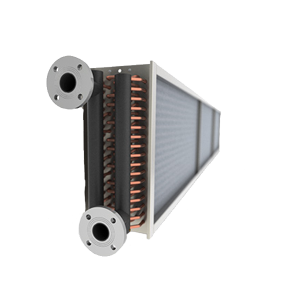

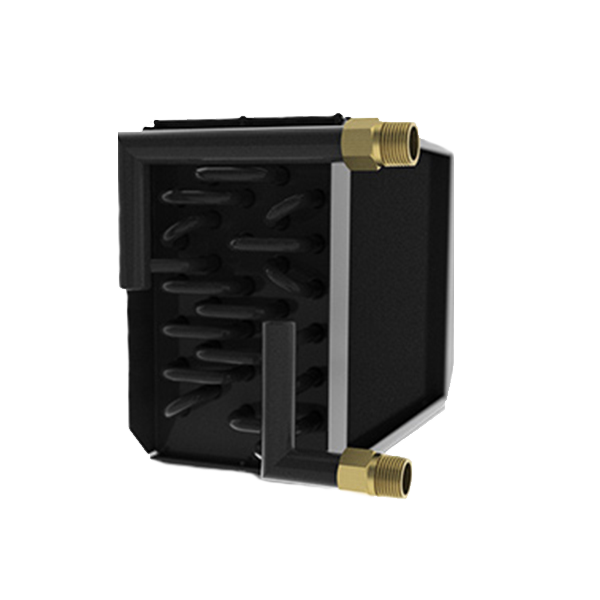

Water Coils (Mono Phase)

Compatible with most fluids in the liquid state e.g water, water-glycol mixtures, oil, diathermic fluids, etc.

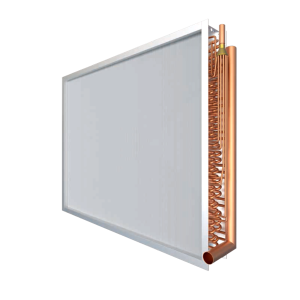

Phase Changing Coils

Evaporators, condensers, reversible for heat pumps. Compatible with all synthetic refrigerants (including A2L), propane & CO2

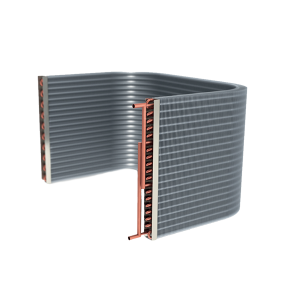

Shaped Coils

Evaporators, condensers, reversible for heat pumps; Compatible with all synthetic refrigerants (including A2L), propane and CO2

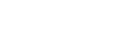

Material Flexibilty

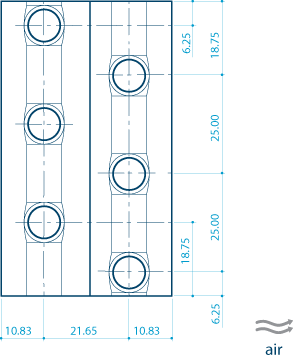

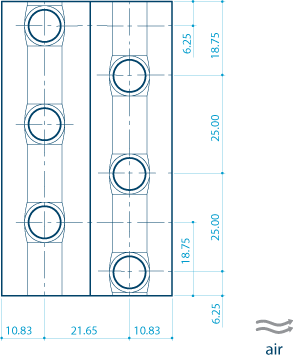

4D Heat Exchanger Coils are highly customisable to suit your specifications or application. Each coil is individually designed, with the fin material selected to take into account the environment in which it is to be located.

Tube material, diameter and wall thickness is selected with the medium, temperature and refrigerant or working pressure in mind and to customers specifications. Casing material can be galvanised or stainless steel to suit harsher operating environments.

Fin material options

Customisable headers

Surface treatments

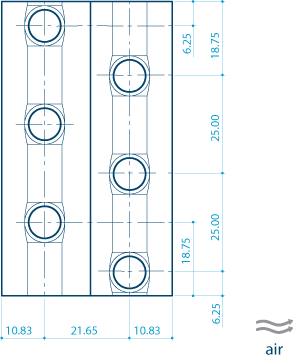

Tube configuration options

Highly customisable frame

| Copper | K65 | Aluminium | Aluminium Pre-Painted | Aluminium Hydrophilic | Aluminium Hydrophobic | Galvanised Steel | Stainless Steel | Brass | |

| Tubes | ✓ | ✓ | |||||||

| Fins | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Frame | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

Coil Selection Software

Dedicated heat exchanger software for thermodynamic calculations; developed in-house and continually updated for maximum ease of use. This ideal tool allows quick and simple calculations for all coil types; heating coils, cooling coils, evaporator and condenser coils. Whilst the software has a rich database of refrigerants and primary working fluid types used across a number of industry sectors, it also allows the user to create and use custom fluid types too.

♦ View and print in PDF format

♦ Save your selections

♦ Broad range of configuration options

♦ High reliability

♦ Sketch generator

Brochure & Coil Enquiry Specification Form

Download

Click to download your copy of the 4D Heat Exchanger Brochure.

Format: PDF

File size: approx 3 MB

Download

Click to download Coil Enquiry / Specification Sheet

Format: PDF

File size: approx 750 kB