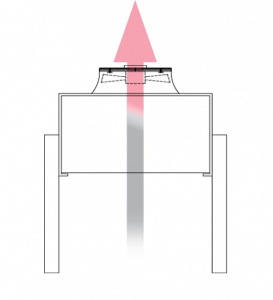

Commercial : 450 / 500 / 630 mm

Industrial : 800 / 910 mm

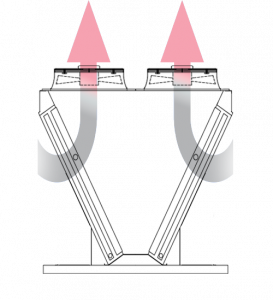

V-Shape : 800 / 910 mm

Oil Coolers : Tailored solutions

Main Product Groups

Light Commercial

Wall Units

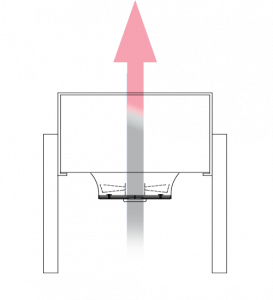

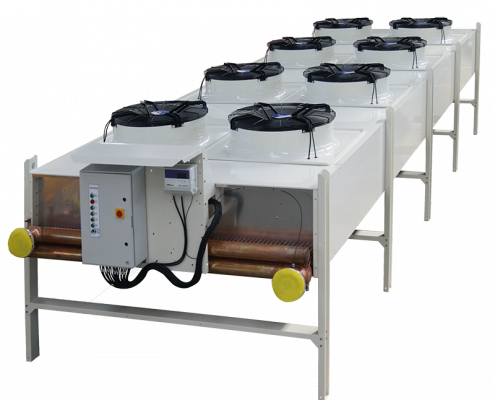

Horizontal ‘Flat Bed’

V-Cooler

Jumbo V

Adiabatic Systems

Maximum Flexibilty & Quality

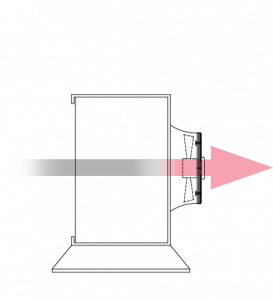

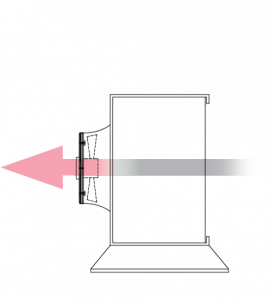

The modular design of our range of dry coolers ensures that we can match all cooling capacities; fan diameters ranging from 450mm to 910mm and a choice of 4,6,8 and 12 pole motors. Heat exchanger coils with geometries to suit most applications and temperatures, with either 5/8″ or 1/2″ tube, fin spacing from 1.6mm to 6mm, with either corrugated or high efficiency fins. Surface treatments include; Epoxy Coating, Electro-Tinned, Blygold Treatment, Heresite Treatment and Electro-fin® E-coat Treatment. Installation flexibility, with either horizontal or vertical unit orientation plus connection handing options.

Fin material options

Customisable headers

Surface treatments

Tube configuration options

Highly customisable frame

Flyer

Download

Click to download your copy of the Dry Cooler Flyer.

Format: PDF

File size: approx 1 MB