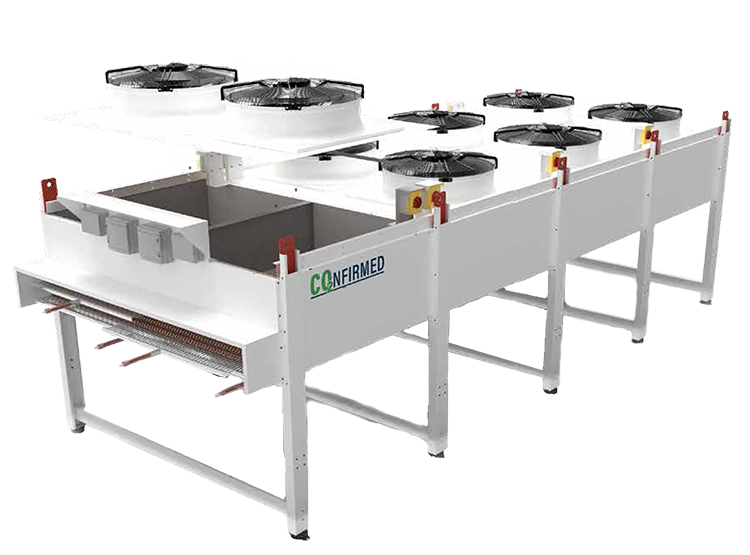

Gas Coolers

The reliable, efficient, and eco-friendly cooling solution for commercial & industrial applications

Transcritical Ready

This line of product, ready to use in CO2 transcritical installations, consists of more than 500 models of axial gas coolers for industrial applications, available in cooling capacities between 15 and 900 KW.

Low Noise & Energy Efficiency

Our gas coolers presents a low noise level and a minimum energy consumption. All models are fitted with EC fan motors as standard. The speed of its fans can be controlled electronically to increase the energy savings

Design Flexibility

A large choice of configurations and accessories are available to meet any specification, plus of our customization capability. With more than 100 different models available, we can match capacities between 15 kW and 900 kW.

High Performance

- With the highest-pressure design in the market PS 140bar, the system can operate at higher pressure, with a benefit in efficiency and capacity, especially at high ambient. For example, at 45°C ambient, capacity can increase by 13% and efficiency by 4.5%.

- Units are also optimized with number of circuits for maximum efficiency at each noise level.

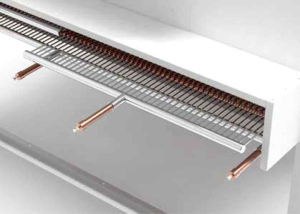

- Staggered arrangement of copper tubes across self-spaced louvered fins.

- The EC Fans adapt to the needs of the installation with minimal energy consumption

Robust Design

Designed with the highest levels of excellence in commercial food preservation sectors – with robust construction and materials developed to withstand every weather condition, including heavy snow and wind loads, guaranteeing a long lifetime.

Materials Flexibility

Stainless steel + K65 copper header materials available.