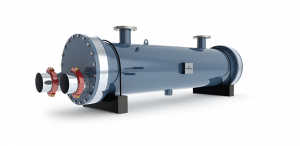

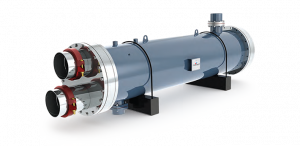

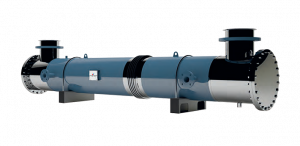

Liquid receivers are pressure vessels with a cylindrical tank and rounded base plates, supplied with accessories such as liquid level indicators and special fittings.

The ideal solution for storing refrigerant charge to absorb fluctuating system loads. The storage capacity of ERH & ERV liquid receivers ranges approximately between 8 and 2,300 liters. Larger customized solutions are available on request. Receivers are available in two series: ERH horizontal and ERV vertical liquid receivers.

Materials

Standard ERH and ERV liquid receivers are made of carbon steel. Refrigerant side connections are either welded or realized with Rotalock fittings.

Tests, standards, operating limits

All liquid receivers undergo pressure tests according to the parameters and procedures prescribed by the certifications below. The assembly, installation, and permanent connection of components and/or accessories must comply with the standards in force. Since liquid receivers are pressure vessels, their safety requirements are regulated by Pressure Equipment Directive PED 2014/68/EU with regard to mechanical design, material selection and use, production and inspection, pressure testing, and final documentation. The certificates of conformity issued under former directive 97/23/EC are valid under the current directive (Art. 48, par. 3, Directive PED 2014/68/EU).